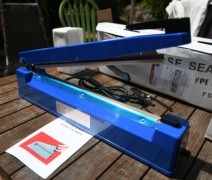

How Do I Choose A Impulse Heat Sealer Sealing Machine?

When selecting a Impulse Heat Sealer Sealing Machine, it is important to have a sense of the material which will be sealed. Try and have the material thickness and width available as this will make your selection process much easier. This will ensure the sealer you purchase is capable of sealing your material. Impulse Heat Sealer Sealing Machine require no warm up time and seal by applying a pulse of energy to the sealing area, followed immediately by cooling. Impulse Heat Sealer Sealing Machine only use power when the jaw is lowered. Zhejiang Tianyu industry Co. Ltd Factory recommend an Impulse Heat Sealer Sealing Machine for any thermoplastic material such as polyethylene (PE) or polypropylene (PP) which requires a lower seal temperature. Impulse Heat Sealer Sealing Machine are easy to use (no warm-up time), economical (electricity used only during sealing process), and safe (no component is always hot).Direct heat (constant heat) sealers maintain constant heat in both jaws. Direct heat sealers use power as long as the machine is turned on. As a result, direct heat sealers possess better heat penetration in order to seal thicker materials.Zhejiang Tianyu industry Co. Ltd Factory recommend a direct heat sealer for materials such as coated aluminum foil, poly cello films, gusset bags, coated Kraft papers, waxed paper, cellophane, mylar, coated PP, and other thicker materials. Direct heat sealers cannot seal polyethylene.